While a fast-changing engineering landscape makes anticipating future needs challenging, we have the mindset to think beyond current trends and develop products that empower our customers into the next decade and beyond.

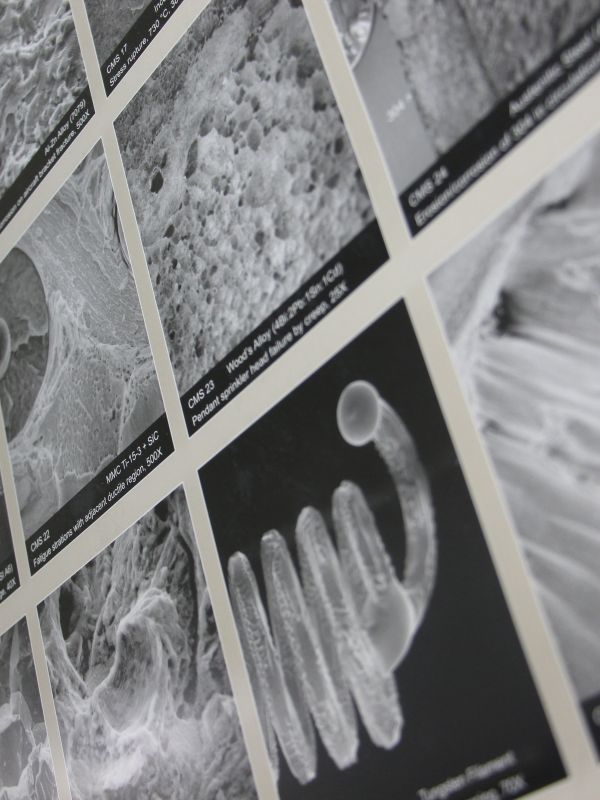

Tasked with exploring and capturing opportunities in material and process development, our research teams are the driving force behind our innovations. Whether it concerns new alloys, coatings or combinations of materials, it is their discoveries we apply when creating or improving product solutions.

New materials often go hand-in-hand with different processing technologies. We therefore leverage our inhouse machinery and tooling capabilities, to tailor the production process to the required product properties from the start.

We also collaborate with a network of research institutes and regional universities, as well as other technology companies. These partnerships generate valuable ideas and provide access to additional resources and expertise, for instance in the field of additive manufacturing.

Our partners include the University of Paderborn, University of Aachen and South Westphalia University of Applied Sciences in Germany and the HAN University of Applied Sciences and Technical University of Delft in the Netherlands. We are also involved in various long-term national and global projects funded by governmental bodies.