Product solutions

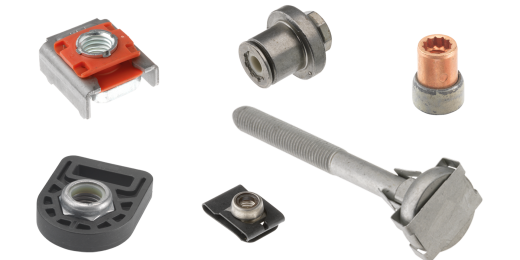

Standard fasteners

We produce a wide range of standard fasteners by the millions every day. These include virtually any type of screws, nuts, bolts, rivets, studs and washers customary to the automotive industry.

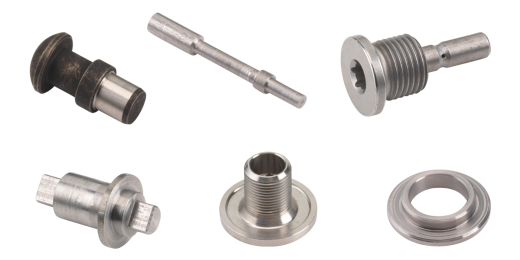

Complex cold formed parts

Often, fastening solutions are a critical part of your product design, influencing functionality, performance and durability. In that case, we produce parts tailored to your application’s exact requirements and can support you with their development as well.

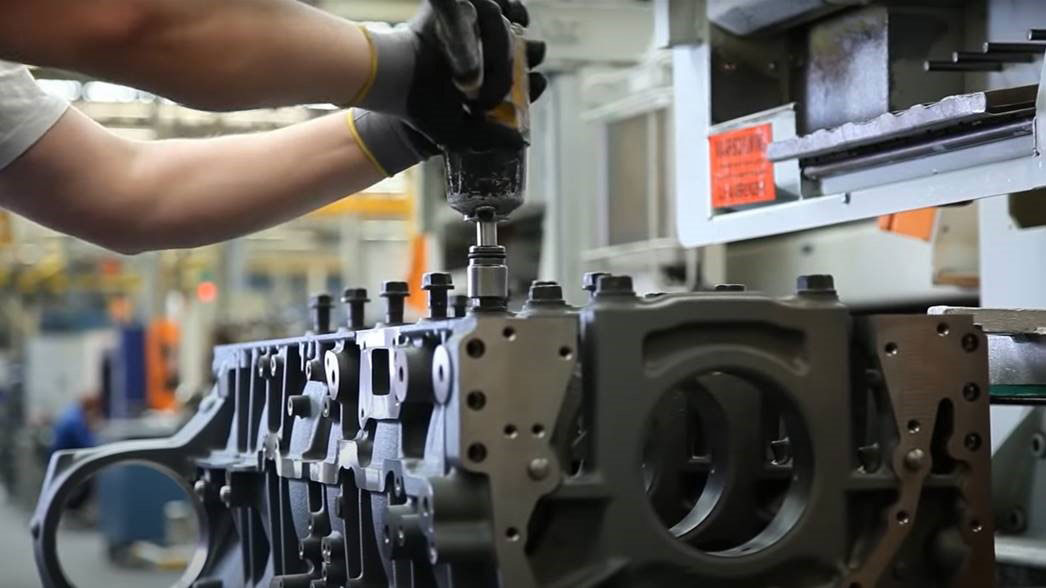

Component subassemblies

You are challenged with making optimal use of labor resources and plant space, while managing against consistently changing production demands. Outsourcing the assembly of components can create greater efficiencies.

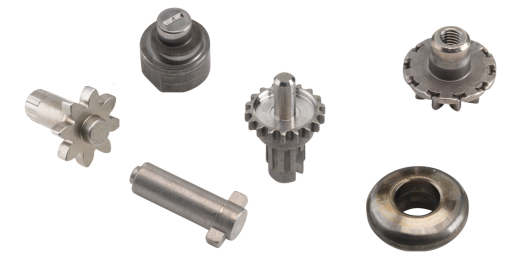

Precision parts

Industries are increasingly looking for non-standard high tensile strength products that meet precise specifications and critical tolerances. Nedschroef is ready to provide custom precision solutions. With meticulous attention to detail, we specialize in creating turned products characterized by tight tolerances, intricate geometry and fast turnaround times.

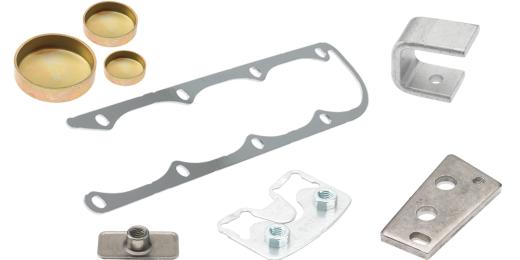

Stamped and bended parts

Nedschroef has the expertise and manufacturing capabilities to form and bend metal parts into virtually any shape, for a wide range of applications. Our comprehensive services extend to providing valuable design insights during the early stages.

Product applications

There is an answer to any fastening challenge. When looking to find a fastener for a specific application, browsing our range of carefully selected multifunctional products may offer a practical solution.