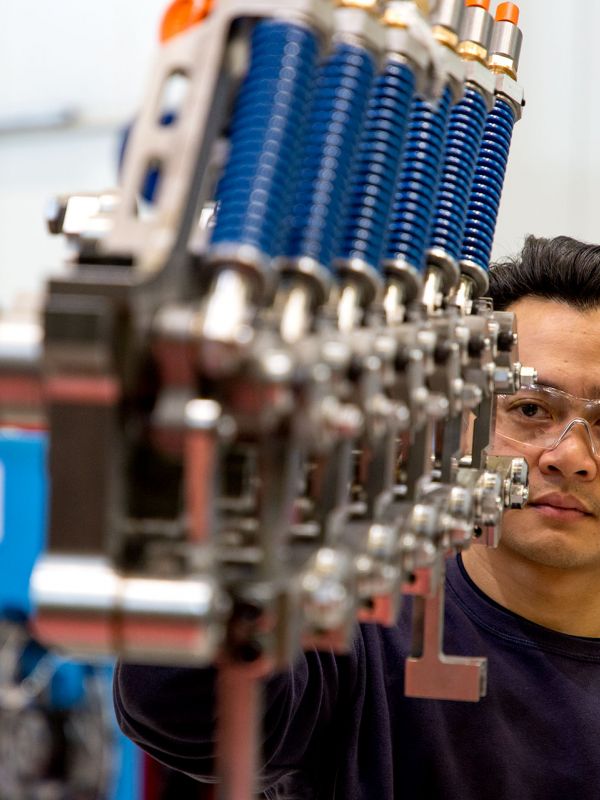

Engineering of systems

Excel your development projects by utilizing our leading engineering expertise and incorporating our latest technologies.

ExploreAutomotive

Assemble your products with our premium quality parts and optimize their design with our engineering expertise.

ExploreFull service provision

Minimize the costs of your C-parts management by entrusting supply chain activities to us.

Explore

Always connecting forward

We help advance the world's leading mobility manufacturers with smart connections.

The fascinating world of fasteners

Watch and listen to our corporate story and discover just how surprisingly interesting fastening technology can actually be.