Constant reliability is one of the key reasons we are a trusted supplier to so many companies in the automotive industry. To ensure we deliver finalized parts with zero defects to our customers in time and in place, we put great effort into quality control.

Testing and sorting

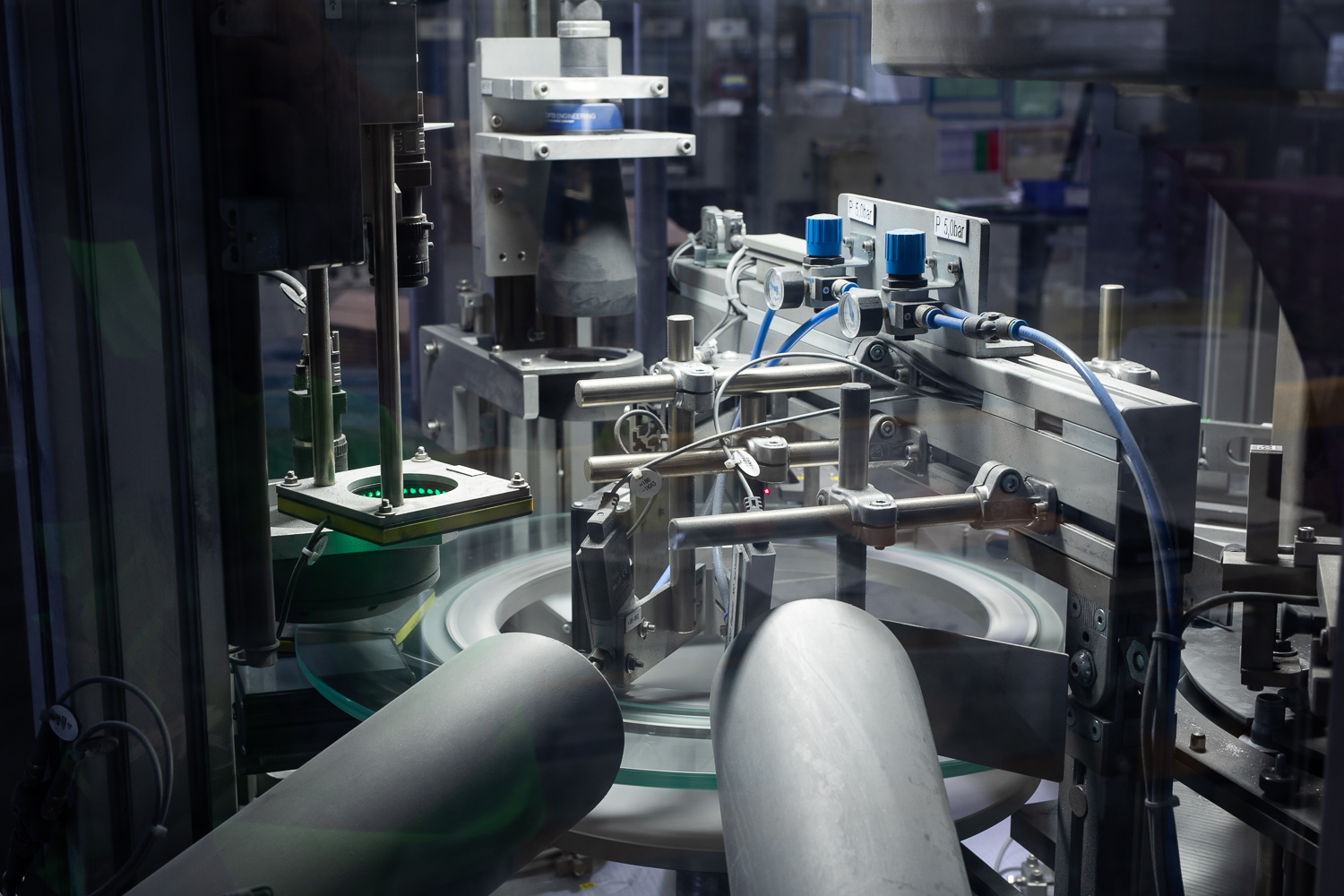

Part samples systematically undergo manual inspections by our machine operators throughout the manufacturing process. In addition, the majority of parts go through an automated testing and sorting process, carried out by machines fitted with cameras and sensors.

Depending on the production phase that parts are in, we test them for deviations in required dimensional tolerances (such as length, thread pitch and drive height), material structure and surface (such as cracks and chips) and mechanical properties (such as tensile strength and preload).

Quality certification

All our automotive production sites are ISO 9001 certified. In addition, they are certified to IATF 16949, the international standard for the automotive industry. To ensure we continuously meet these standards, audits are periodically conducted at our locations.