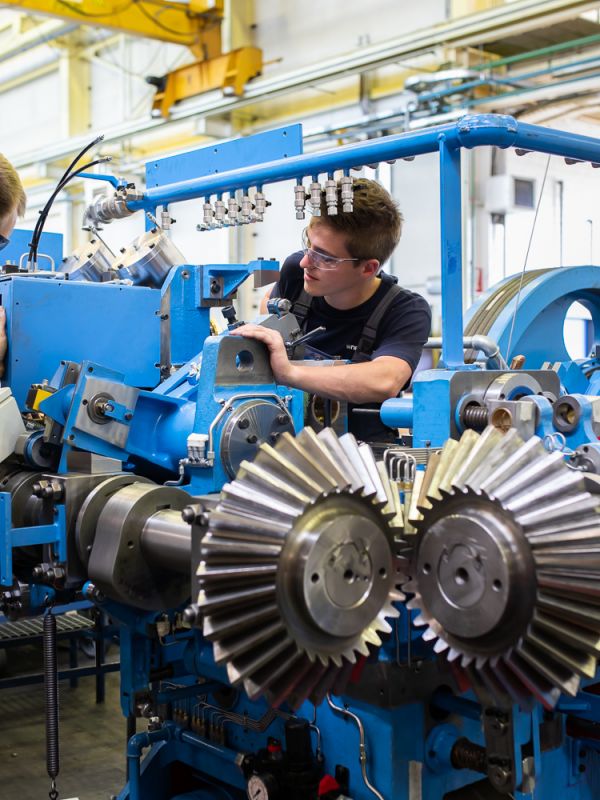

After many years of operation, the main mechanical components of machines are usually still in good condition. Yet, control and drive technology continues to advance steadily over time, making newer machines perform better. Our retrofitting and reconditioning service provides you with the same benefits a modern machine has to offer, only then by extending the lifecycle of your existing machinery.

The retrofitting and reconditioning activities we perform include:

- Study and initial validation of the machine condition

- Disassembly of the structural components

- Inspection and evaluation of all components

- Adjustment, repair or replacement of functional components

- Machining and grinding of components

- Cleaning and painting

- Replacing and upgrading the electrics, pneumatics and hydraulics

- Assembly and adjustment of the structural components

- Compliance with standards and regulations

- Installation and commissioning

- Calibration, functional testing and acceptance by the customer

Updating technology

Our retrofitting service focuses on keeping machine technology up to date. With this we ensure that older machines continue to deliver the performance and quality normally expected from a new one, throughout the superior lifecycle typical of our products. By carrying out a software upgrade or installing complementary modules, we add functionality that increases the level of automation and makes operation easier.

Renewing components

If customers have been encountering operational difficulties or if our onsite inspections have identified issues with certain machine parts and wear tools, our reconditioning approach can be required. This means we completely disassemble a machine, and then rebuild it with new parts, to deliver an operation level comparable to that of a brand-new machine. Reconditioning can also be applied to a specific selection of parts instead of the entire machine.

Our retrofitting and reconditioning services result in:

- Minimized investment costs

- Increased level of automation

- Extended equipment lifetime

- Improved machine reliability

- Increased quality and productivity

- Enhanced ease of operation

- Advanced monitoring capabilities

- Compliance to latest standards